Thursday, December 17, 2009

Building the armature for the stems.

The armature for the stems started with another laser scanned enlargement from Gator Products. The juncture of the three stems was built using a high density foam to provide extra strength. The longest stem is made from a hand-bent piece of 3/4" metal conduit and the shorter stems are fashioned from thick aluminum wire and then coated in sculpting wax to provide additional strength before they are covered in sculpting clay.

Tuesday, November 3, 2009

Applying the seams.

The last thing to sculpt before I apply the second texturing pass are the seams along the back of the bean Pods. Seams as shown are in thier initial state and still need to be refined further.

Transition between applied clay and texture.

There are still a few areas to work with texture. You can see low areas in this photo that will be filled in with additional clay as I texture.

Texture details

This is the initial texture. There will be another texturing pass made over the entire piece to make sure there are no low/high areas that still need to be dealt with and then I will then go through and smooth all of the texture off of the high points to provide contrast.

Bean Pods totally covered with clay.

At this point the pods are completly covered in clay and most of the surface has had the initial texture put on.

Sunday, October 25, 2009

Clay is being applied to the surface.

I am applying a layer of oil based clay. Because the enlargement was so precise, in most areas I am only having to add 1/8" to 1/4" thickness of clay. The stems of the Bean Pods will be made and set in place later as a separate piece.

Painting the foam with a layer of hot wax.

I am painting the surface of the foam with a layer of hot wax. This serves two purposes, it will seal and strengthen the foam, and it also provides a better surface for the clay to adhere to.

Back veiw of the Bean Pods.

The Pods are in the studio and I have added 1" steel pipe for an armature to hold them upright during the sculpting process. Holes were drilled into the foam so that the pipe could be inserted into the foam an then glued in place. The Bean Pods are now very rigidly held in place.

Pods in the studio all together with 1" steel pipe armature in place.

I want to say THANK YOU to Gator Productions in Loveland, Colorado for doing such a great job with the foam enlargemnt.

Saturday, October 24, 2009

Ready to be untaped.

After the glue has dried and the tape is removed the Pod will be hand sanded to remove any excess glue and to smooth down any seam lines on the surface.

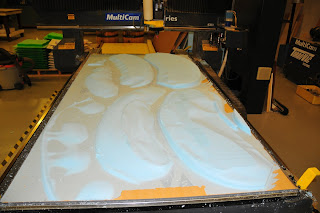

Bean Pods starting to appear.

At this point large areas of foam are being removed and a larger cutting blade is being employed. Additional passes will be made over the foam with refining blades to get a more finished surface.

Subscribe to:

Comments (Atom)